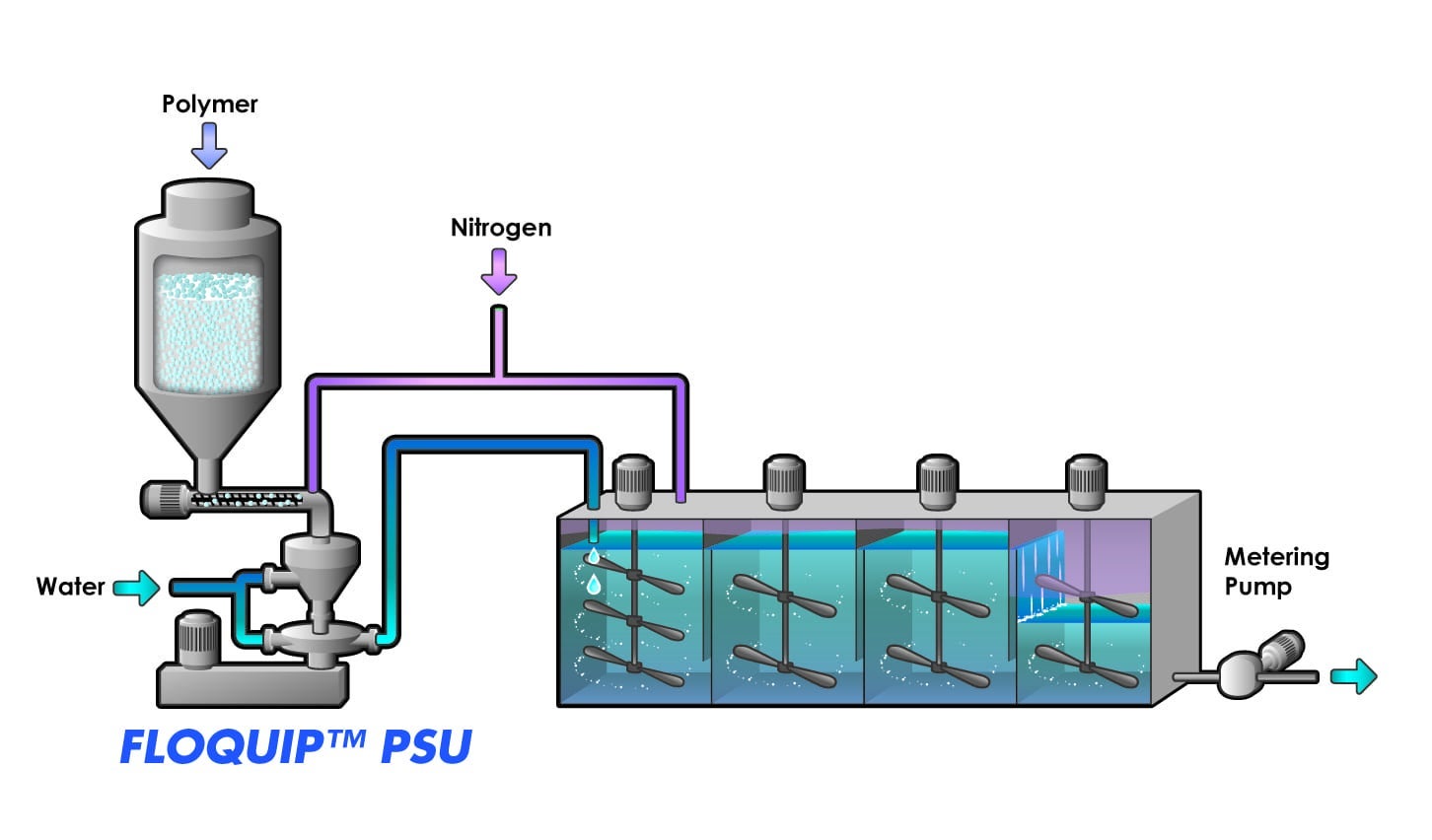

The PIU relies on the following dissolution principle for polymers: Powder-grade polymer coming from a storage tank is proportionally mixed with water to create a polymer solution, using a patented FLOQUIP™ PSU (Polymer Slicing Unit). After hydration and maturation of the polymer solution are complete, it is then diluted and injected without filtration into wells, in accordance with injection rate and pressure guidelines. Nitrogen blanketing is used to preserve the polymer during the dissolution process.

SNF has developed specific equipment to deal with all challenges faced in polymer applications, in order to guarantee the most cost-effective solutions, while paying close attention to reducing environmental impact.

FLOQUIP™ Polymer Injection Unit (PIU)

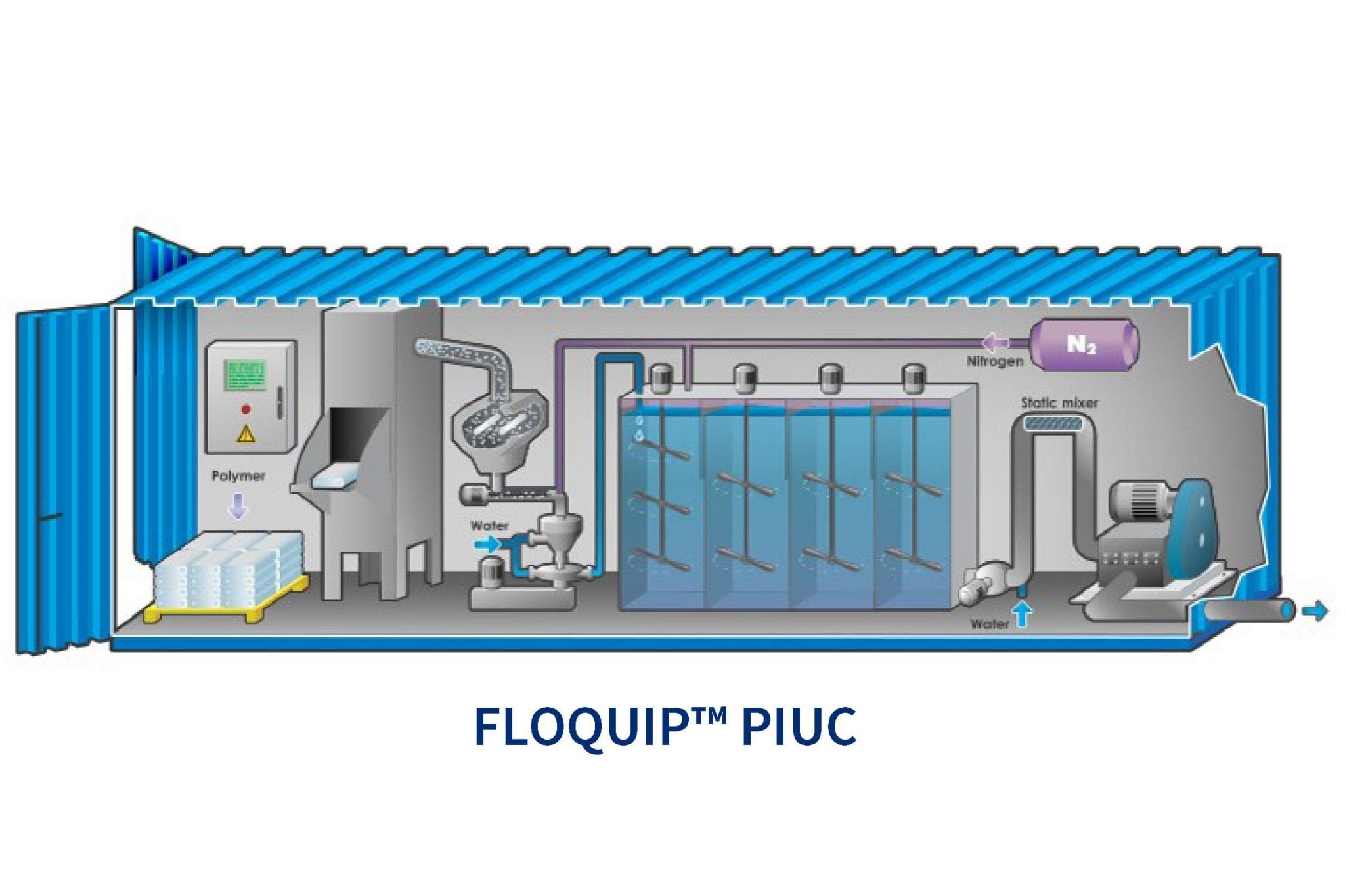

SNF has developed pre-designed and standardized modular solutions, enabling the injection of polymers into wells at specified viscosities and flow rates. These modular PIU (Polymer Injection Unit) systems consist of 40 ft. HC standard sea containers for easy transport. They are assembled together, integrating all of the required equipment for polymer injection and dissolution.

Modular injection systems can be connected to existing water injection lines, without the need to develop new infrastructure. These units allow for quick installation and start-up.

Modular systems enable incremental development from pilot to full-field solutions with limited and controlled risk, thereby reducing costs and delivery lead times.

POLYMER SOLUTION PREPARATION

POLYMER INJECTION UNIT CAPACITIES

SNF offers several models of the Polymer Injection Unit (PIU) to dissolve varying quantities of polymer utilizing our FLOQUIP™ Polymer Slicing Unit (PSU) technology.

Typical PIU models, primary design purposes, and capacities are outlined below.

Our FLOQUIP™ PIUC model is the most compact injection unit available (integrated into one 40 ft. container). It was specifically designed to minimize overall equipment size and footprint in the field.

Polymer Injection Unit Models and Related Capacities

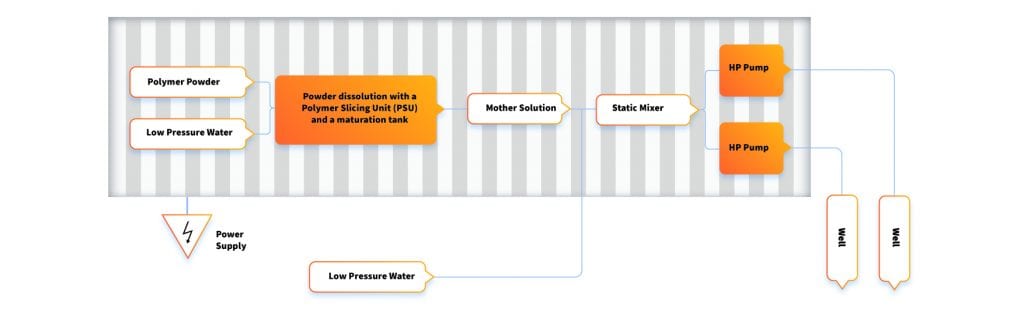

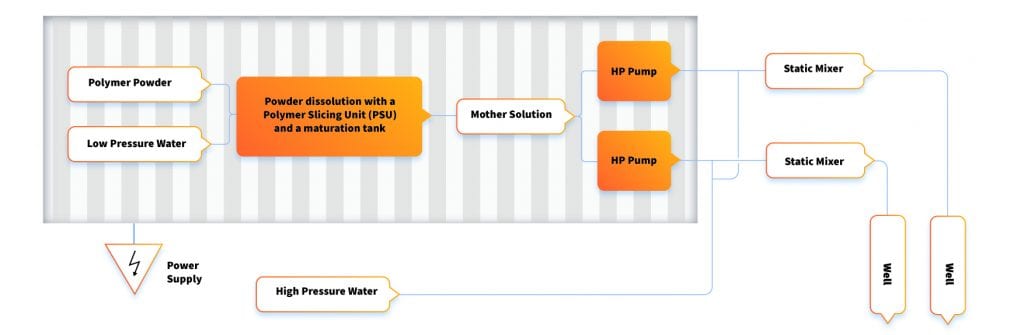

PIU Injection Configuration

There are different possible options for polymer flooding depending on site configuration.

Dilution with water can be done at low or high pressure.

VPR and LPR enable controlled injection in each individual well without degrading the polymer.

IF HIGH-PRESSURE WATER IS AVAILABLE

IF ONLY LOW-PRESSURE WATER IS AVAILABLE