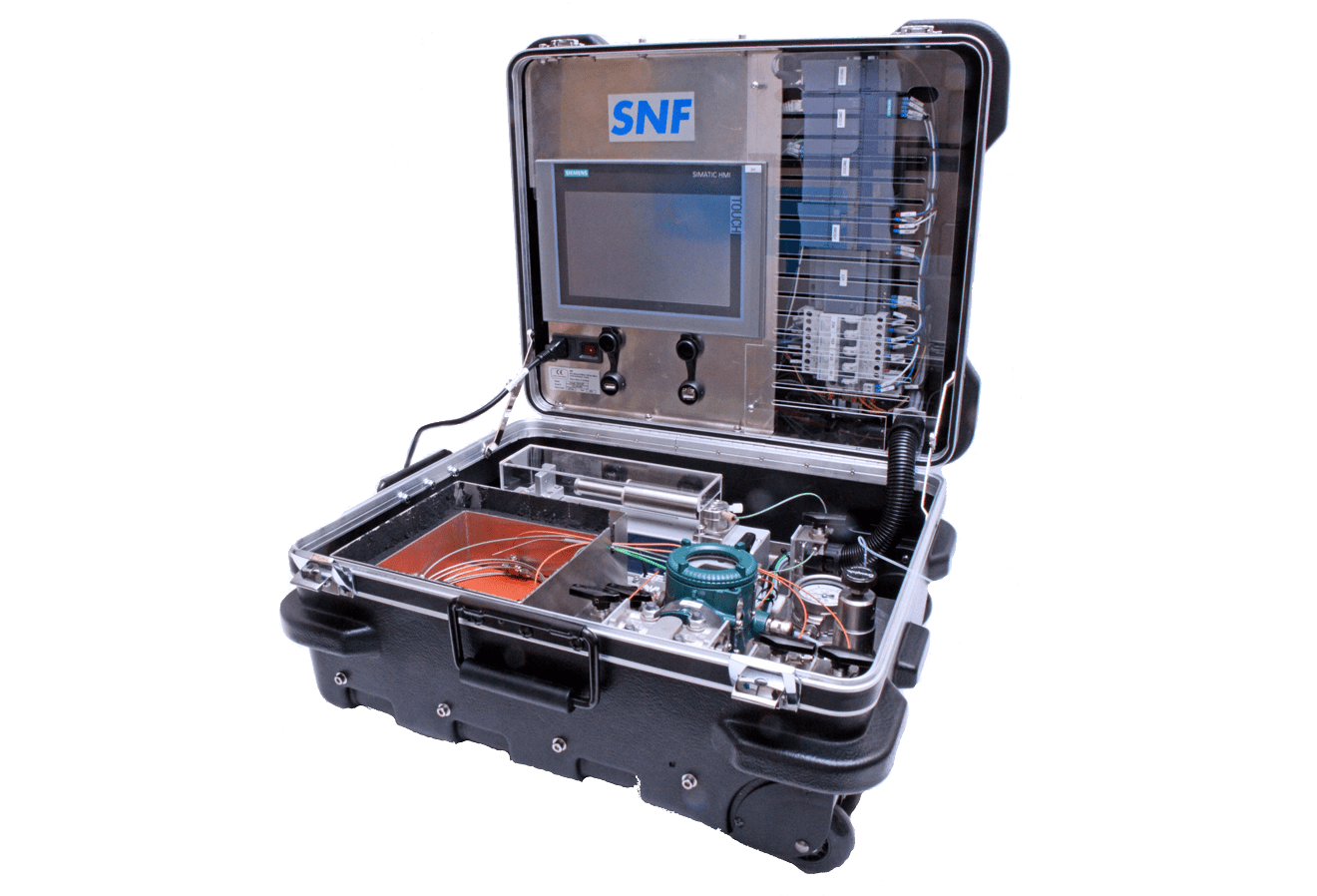

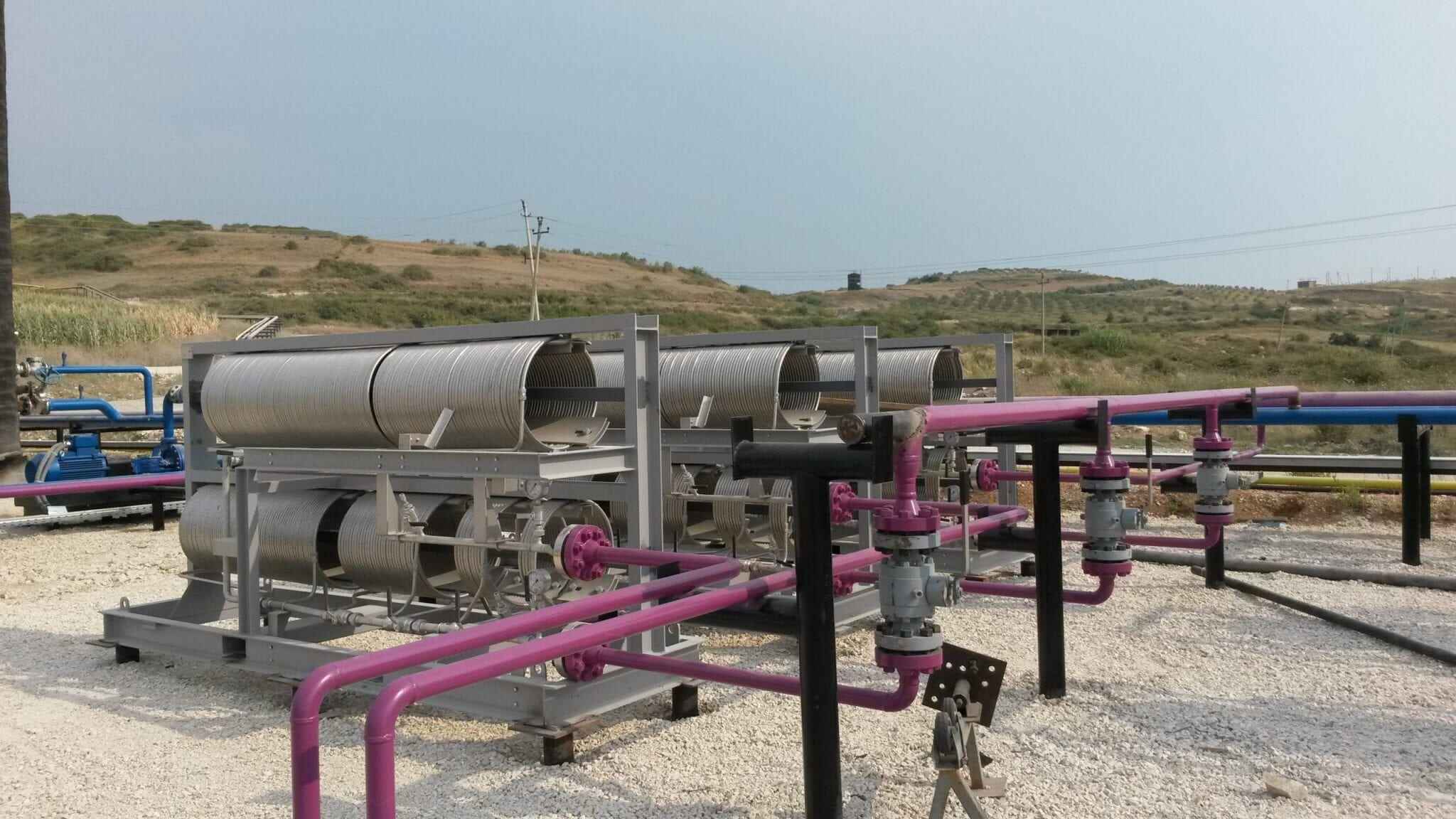

Mobile Injection Unit

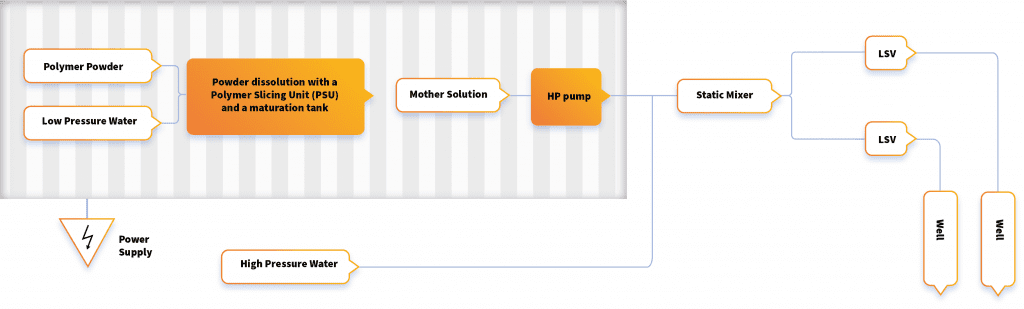

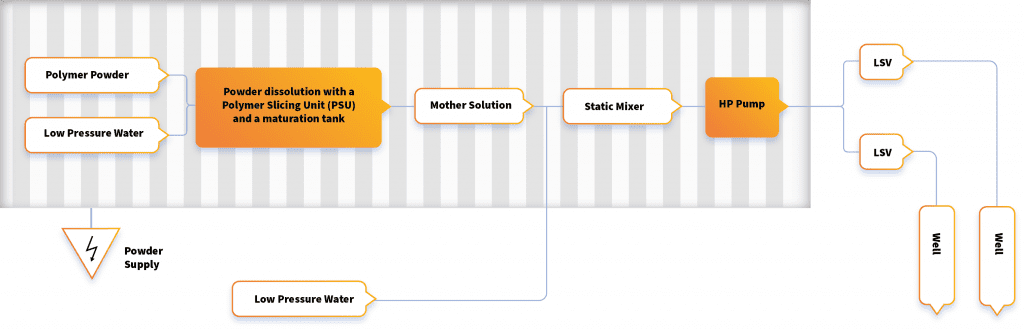

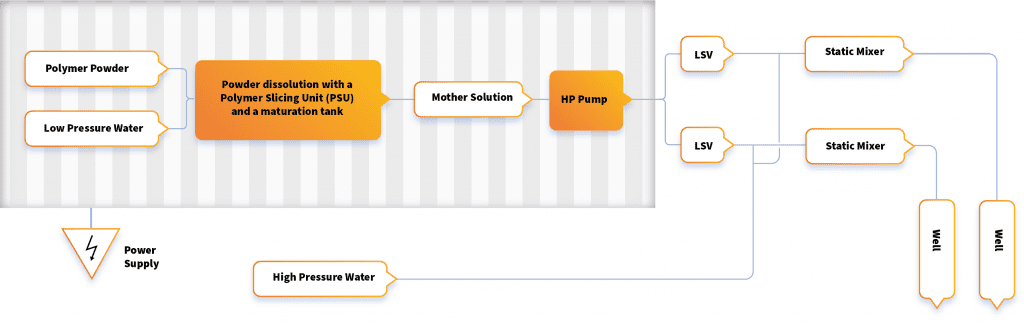

SNF has designed and engineered a mobile, high-output polymer injection unit using patented technology to speed hydration and delivery of dry, polyacrylamide-based friction reducers (FR). Featuring an open design, the POWDERFRAC™ X eliminates the non-productive time and is a safe, reliable, and easy to operate/maintain system for preparing dry FR solutions.

When used with SNF’s FLOJET™ DRP X products, POWDERFRAC™ X offers a cost-effective, easy-to-use, and environmentally-friendly solution for applying friction reducers in hydraulic fracturing stimulation.