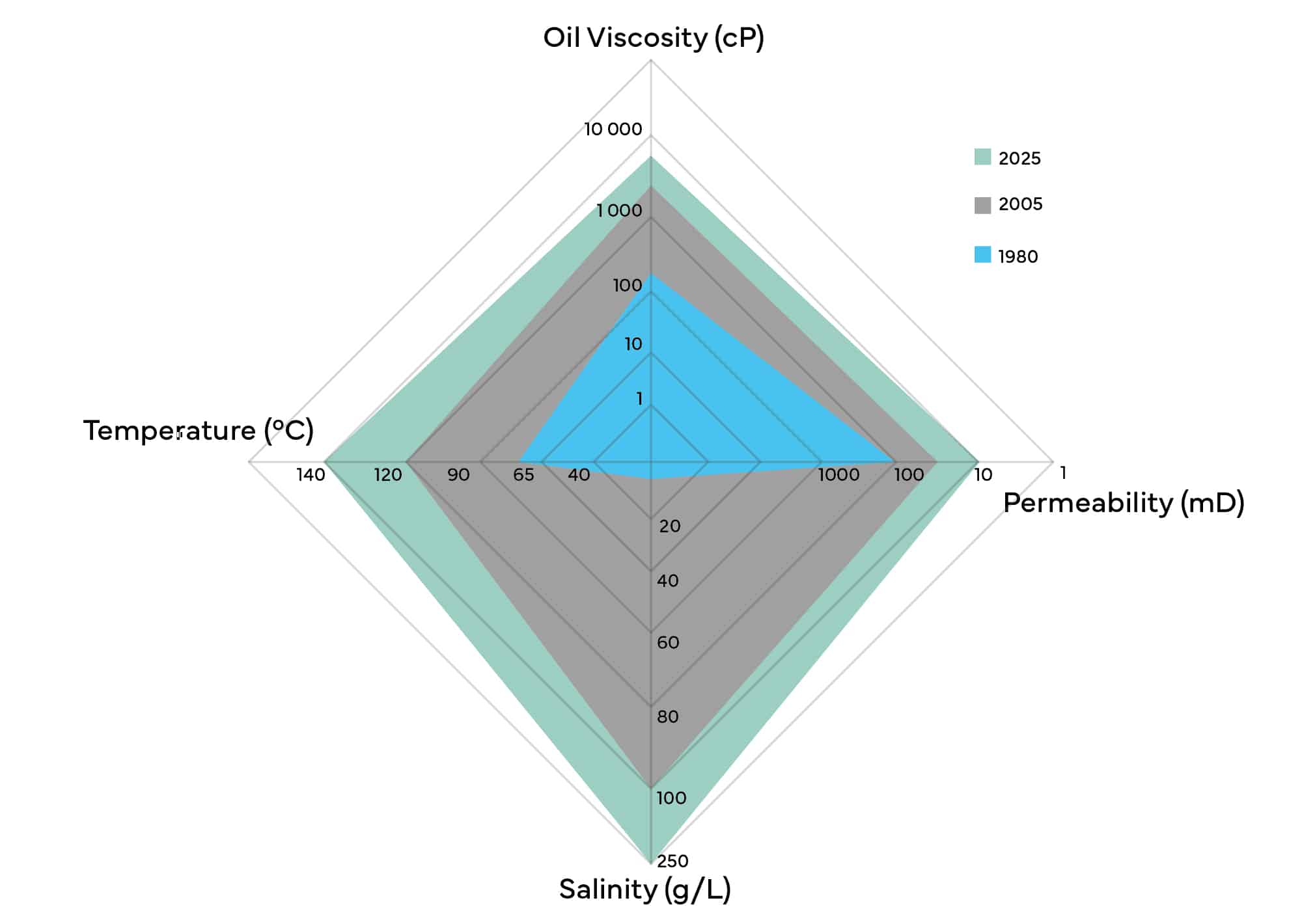

Over the past decades, polymer flooding has undergone significant advancements. Today, this well-established C-EOR technology can be successfully applied in more challenging reservoirs — including those with higher salinity, elevated temperatures, or lower permeability. These improvements result from SNF’s continuous innovation in water-soluble acrylic polymer chemistry.

SNF: The global leader in Chemical EOR, delivering integrated chemistry, project design, engineering, and logistics for reliable project success.

SNF leads the advancement of viscous water injection technologies—delivering complete Chemical EOR solutions that combine polymer innovation, engineering expertise, and global logistics support. Our integrated approach ensures reliable, efficient, and sustainable oil recovery for operators worldwide.

SNF supports viscous water flooding projects in more than 60 countries through an integrated network of production facilities, hubs, and service teams. We manage the entire supply chain, from manufacturing to on-site delivery, to ensure reliable polymer availability and continuous project execution worldwide.

SNF End-to-End Polymer Solutions for EOR

Chemicals

- HPAM & Sulfonated Co- and Ter-polymers

- High Temperature High Salinity Polymers

- Delayed Viscosifying Polymers

- Powders and High-Active Liquid Forms

- Surfactants – Alkali – Solvents

Services

- Reservoir / Field Assessments

- Commissioning / Start-up Training

- O&M Assistance Optimization Assistance

- Performance Monitoring

- Lab Studies

Equipment & Engineering

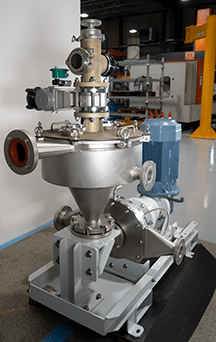

- Polymer Slicing Units (PSU)

- Modular Skids

- Polymer Injection Units (PIU)

- Turn-Key Systems

- EPC Contracts

Enhanced Oil Recovery (EOR): Proven Polymer Performance

For more than five decades, SNF has led the evolution of Chemical Enhanced Oil Recovery (CEOR) — from the earliest polymer flooding field trials in the 1970s to today’s large-scale viscous water injection projects. Our continued innovation has made viscous water EOR a reliable, cost-effective, and field-proven solution for maximizing oil recovery.

As the global leader in polyacrylamide production, SNF delivers complete, end-to-end solutions that integrate polymer design and formulation, equipment engineering, logistics coordination, and on-site technical support. Each polymer system is engineered to perform in demanding reservoir environments—high temperature, high salinity, or high heterogeneity—ensuring consistent viscosity control and injectivity over time.

With more than 500 successful viscous water and polymer flooding projects worldwide, SNF helps operators boost recovery factors, reduce water production, and lower carbon intensity per barrel produced. Through seamless integration of chemistry, engineering, and logistics, SNF transforms viscous water injection into a scalable, sustainable recovery strategy for the future of oil production.

Solutions We Provide

SNF delivers complete CEOR solutions that turn viscous water injection from concept to full-field success. Our expertise spans chemical innovation, project and engineering design, and logistics management, ensuring that every project is executed efficiently and reliably.

Our solutions include:

- Project Screening & Feasibility: Reservoir, brine, and economic assessments to confirm the potential for viscous water or polymer flooding.

- Polymer Design & Formulation: Custom molecular weight and monomer composition (including ATBS technology) optimized for viscosity retention, salinity tolerance, and injectivity.

- Pilot & Field Implementation: Design of injection strategies, support for simulation, and organizational planning for safe and efficient execution.

- Equipment & Engineering: Purpose-built Polymer Slicing Units (PSU) and modular injection skids enabling efficient polymer dissolution and viscous water preparation on site.

- Logistics & Supply Chain Coordination: Global production and distribution network ensuring reliable, timely supply and project continuity.

- Monitoring & Optimization: Continuous tracking of injectivity, polymer performance, and recovery to maximize field output.

- Training & Knowledge Transfer: Empowering operators and engineers with best practices for viscous water handling and field operation.

SNF’s integrated approach combining chemistry, engineering, and logistics helps operators increase recovery, extend reservoir life, and reduce environmental footprint.

WHAT OUR CUSTOMERS ARE SAYING ABOUT SNF:

“I have been working alongside SNF technical staff for some years now, both through their involvement in a JIP with Arne Skauge in Norway, and also on one-to-one field polymer flooding applications around the world. I have always been very impressed by their openness to work together, their technical ability, and their receptiveness to new ideas. SNF has been a great supporter of our ideas on modelling viscous fingering and the subsequent benefits of polymer flooding of viscous oils. They have fearlessly taken these ideas into the field with genuine enthusiasm and great success.”

– Kenneth Sorbie

Professor

Heriot-Watt University

![]()

“Whilst working in Shell R&D, deploying ASP flooding trials in a few countries I was fortunate to work with SNF. I found their staff to be highly reliable, open, honest and capable. We worked through a few operational challenges which were resolved due to their can-do attitude and significant depth of capability.”

– Andrew Parker PEng, Retired

Former cEOR R&D Lead

Shell E&P

Product Offerings

Pushing the Limits of Polymer Flooding

The Right Cost-Effective Polymer for Your Reservoir

SNF helps you select or design the polymer that perfectly fits your reservoir conditions. All key parameters are carefully considered to ensure a reliable and cost-effective recovery process.

Regardless of the polymer chemistry or delivery format, SNF guarantees the highest quality standards through extensive testing and characterization:

- Polymer dosage to determine the optimum injected-fluid viscosity and estimate operating costs (OPEX)

- Thermal stability to ensure consistent reservoir sweep efficiency over time

- Chemical compatibility to prevent polymer or additive precipitation and degradation

- Laboratory core-flood injectivity tests to confirm reservoir integrity and injectivity

Depending on your field characteristics, an existing SNF polymer may provide the ideal fit — or our experts can design a custom-engineered solution to address your specific challenges.

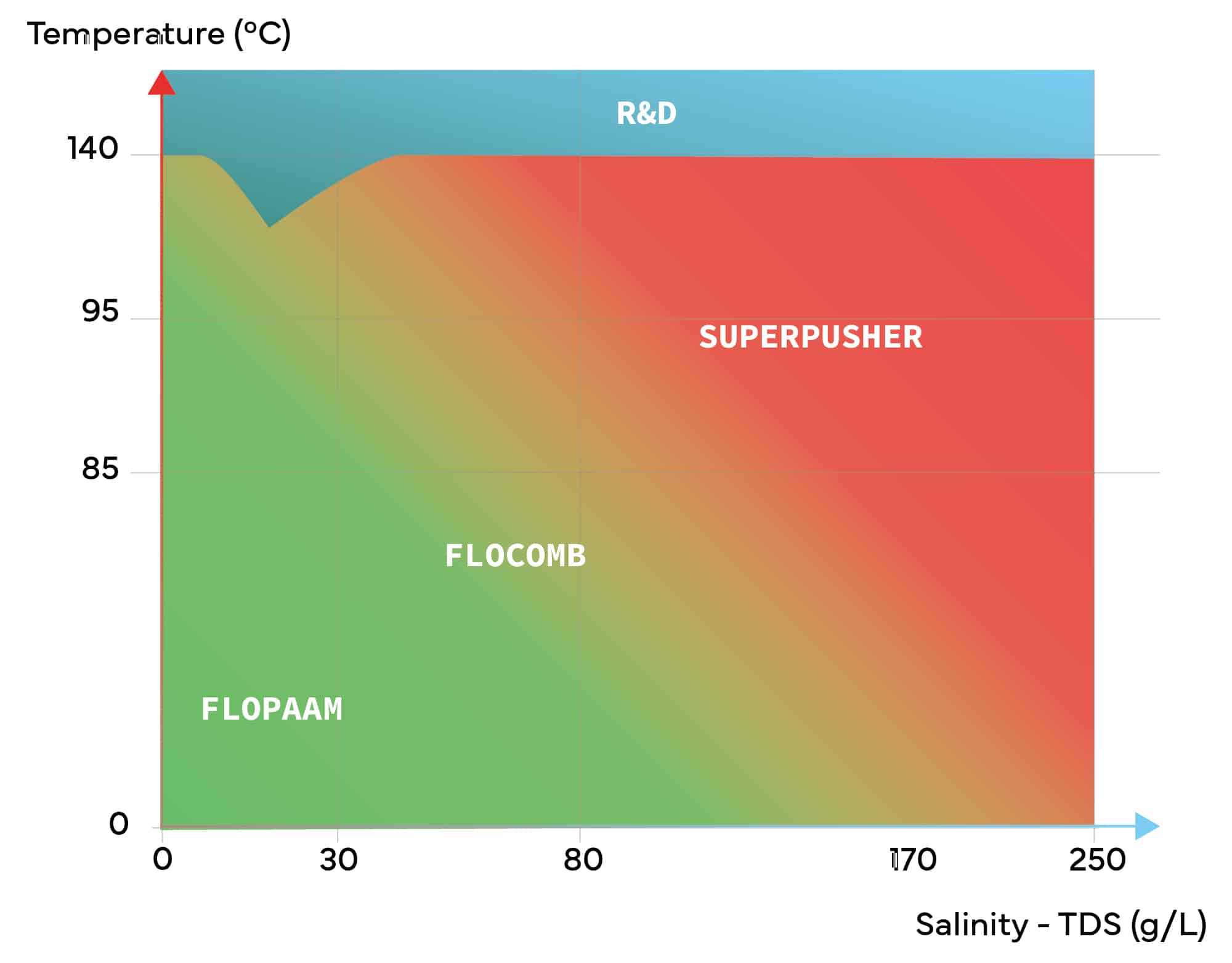

Our powder polymer portfolio covers a broad range of salinities and reservoir temperatures, including:

Flopaam™ – Anionic polymers suitable for mild to medium-temperature reservoir conditions

Flocomb™ – Ultra-high molecular weight anionic polymers for medium to highly permeable reservoirs

Superpusher™ – High-performance sulfonated polymers designed for harsh conditions

Solutions for Offshore Operations

For offshore environments where footprint and logistics are critical, selected polymers are also available in high-solids liquid form, also known as inverse emulsions. These formulations offer easier handling, optimized storage, and simplified injection.

Equipment & Engineering

At SNF, engineering excellence drives every aspect of our Enhanced Oil Recovery (EOR) solutions. With more than 200 dedicated Oil & Gas engineers, we deliver complete design, fabrication, and integration services for polymer injection systems, including alkali and surfactant packages, water treatment facilities, and produced-water management units. From modular Polymer Injection Units (PIUs) to advanced FLOQUIP™ equipment and digital monitoring tools, SNF transforms complex EOR projects into reliable, efficient, and scalable field operations—engineered from concept to commissioning.

Polymer Equipment and Engineering for EOR

Transportation & LogisticsUnmatched Scale, Reliability, and On-Site Expertise

SNF delivers Enhanced Oil Recovery’s most comprehensive polymer logistics and site-support program—an integrated, vendor-managed supply model that no competitor can match. With decades of combined applied polymer experience, our team ensures that customers receive the right product, at the right time, backed by the technical expertise required for peak application performance, to EOR projects around the world.

SNF’s North American logistics network moves high-volume polymer products from our U.S. manufacturing plants to Alberta and Saskatchewan through dedicated bulk rail hopper cars, intermodal containers, bulk containers, and 750-kg bags, all coordinated through our regional hubs. Product-specific storage silos feed dedicated pneumatic trailers for streamlined on-site delivery, inventory tracking, and rapid replenishment based on live consumption data.

To guarantee operational continuity, SNF maintains significant emergency inventory for supply chain resiliency in Alberta—ensuring supply stability even during disruption or demand spikes. Standardized connection systems and efficient unloading procedures minimize downtime, delivering a seamless supply experience from plant to field.

SNF brings together manufacturing scale, specialized logistics, deep technical knowledge, and on-site service—creating a fully integrated supply and support model that keeps operations running and performance optimized.

Logistics Excellence

SNF’s transportation model combines global manufacturing strength with local delivery precision.

- Vendor-owned and managed inventory (VOMI)

- Bulk rail hopper car supply

- Product-specific pneumatic trailer delivery to site

- Eight weeks of supply chain coverage + emergency stock

- Real-time silo and warehouse inventory monitoring

Site Services & Operational Support

Our field teams ensure that polymer is not only delivered—but performing.

- Equipment audits

- Dosage profiling

- Hydration efficiency checks

- Residual polymer detection

- Daily/weekly performance reporting

- Quarterly product selection testing

Polymer Related Services

SNF delivers complete field services to ensure the successful implementation and sustained performance of viscous water and polymer flooding projects. Our expertise extends far beyond chemical supply — we provide the chemistry, equipment, field expertise, and logistics required for flawless and efficient operations.

COMPREHENSIVE EOR CHEMISTRY

SNF supplies a full range of Enhanced Oil Recovery (EOR) chemicals, including polymers, surfactants, alkalis, and specialty additives, all formulated to match specific reservoir conditions.

ENGINEERED EQUIPMENT SOLUTIONS

To guarantee consistent polymer solution quality, SNF designs and delivers fit-for-purpose equipment such as Polymer Slicing Units (PSU) and modular mixing and injection skids. Each system is engineered for reliability and simplicity, ensuring dependable performance even in remote or challenging environments.

ON-SITE EXPERTISE AND LOGISTICS COORDINATION

Our teams provide on-site technical supervision, commissioning and decommissioning, and operational support, maintaining stable injection and precise viscosity control. Through integrated logistics coordination and field operations management, we ensure timely delivery, efficient product handling, and seamless field execution throughout the entire project lifecycle.

PROVEN GLOBAL EXPERIENCE

Backed by decades of field success and a global support network, SNF combines chemical, engineering, operational, and logistical excellence to deliver safe, efficient, and high-performance EOR projects — from start-up to completion.